Introduction

Simultaneous generation of geometry and microstructure

高次機能加工学は、形状の創成と機能の創出を同時に実現することを狙いとする加工技術で、機械(製造技術)と材料技術の境界に位置しています。本研究室では、変形加工理論解析・変形加工システムの開発・材料組織制御などの基礎研究に取り組んでいます。

Hyper-functional forming, which locates at interdisciplinary field between production technology and materials technology, is aimed at generating geometry and mechanical properties of formed product. We are carrying out investigations into the basic field of hyper-functional forming as theoretical analysis of metal forming, development of new forming systems and micro-structure control of metallic materials by forming.

高次機能加工学

Hyper-functional Forming

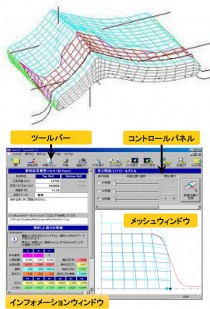

- 形状および組織制御のための塑性加工CAEシステム

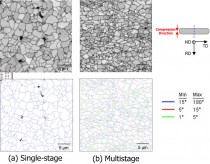

Forming CAE system for the control of geometry and microstructure - 幅拘束大圧下制御圧延によるバイモーダル薄鋼板の製造

Width-restricted heavy-reduction controlled rolling process - 半溶融・半凝固による成形と組織制御

Semi-solid forming and microstructure control - 超軽量構造実現のための金属板の温間プレス成形

Warm forming of metallic sheets for ultra lightweight construction - 繊維強化複合材料薄板(CFRP sheet)の成形加工

Forming of carbon fiber reinforced plastics sheet

ステンレス鋼の半溶融・半凝固加工

Semi-solid forming of type 304 stainless steel

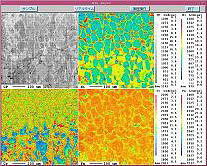

The concentration profile of the two-phase semi-solid state of type 304 stainless steel is obtained by EPMA . The liquid and solid parts are clearly shown as regions with different concentrations of Ni and Cr.

単パスおよび多パス加工による細粒鋼の創製

Ferrite grains using image quality maps (upper) and grain misorientation maps (lower) obtained by EBSP analysis

東京大学生産技術研究所 機械・生体系部門

Department of Mechanical and Biofunctional Systems

教授Professor

教授Professor

柳本 潤Jun Yanagimoto

e-mail: yan@iis.u-tokyo.ac.jp

http://www.cem.t.u-tokyo.ac.jp/